New and ongoing projects utilize Bostec's unique product capabilities

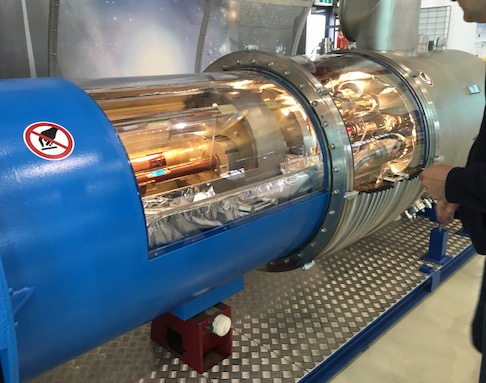

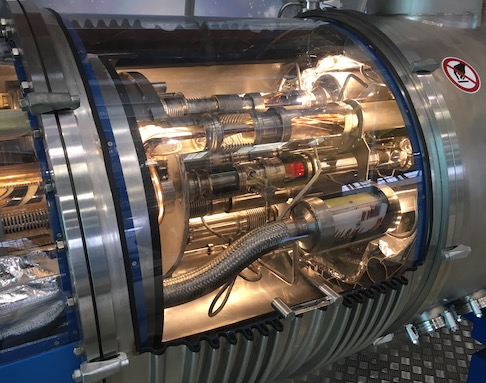

SPS Injector

Investigation Tour

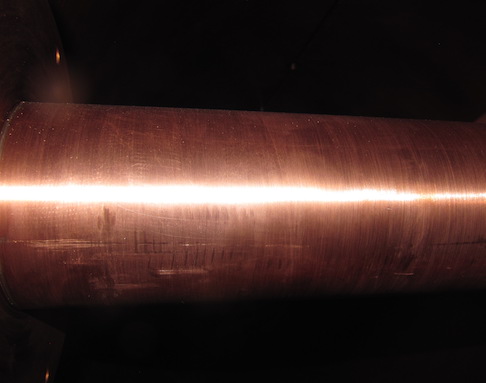

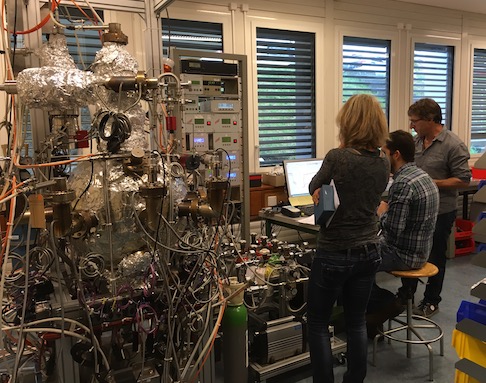

Bostec was recently awarded a multi-year exclusive contract to supply CERN with precision metal seals. To earn this contract, Bostec engineers worked with CERN over a 3 year period to solve persistent leakage problems in UHV joints covering aluminum and copper seals throughout the LHC, as well as subordinate components such as the SPS injector. The result of that collaborative effort was a redesign of most seals, incorporating special technologies developed by Bostec. The newly designed seals were backward compatible with existing CERN flanges, but with much improved results. Assembly yields now are near 100%.

In addition, Bostec tackled high failure rates with CERN’s energized seals. That obsolete design required high tensile strength metallic bolts that became nuclear activated over time. The result of Bostec’s redesign effort has been replacement of all spring energized seals with Bostec’s X-Energized seals. X-Energized seals utilize low-load aluminum fasteners that do not nuclear-activate, making the working environment much safer for technicians.

1st Qualification - normal connection

2nd Qualification - large misalignment

2nd Qualification - large gap

3rd Qualification - aluminum seal, aluminum flange

Bostec engineers worked with FermiLab to solve persistent leakage problems with their diamond aluminum seals. Failures were principally attributed to improperly designed seals that had insufficient crush zones to conform to existing flanges, wrong material substrates, and poor tolerances. Bostec redesigned all seals to provide protective shoulders to shield critical surfaces from damage and aid technicians in installation. Before and after results have been significant. Gaskets failures with the old design were in the neighborhood of 50%. Using Bostec’s new designs, yields are near 100%.

Investigation

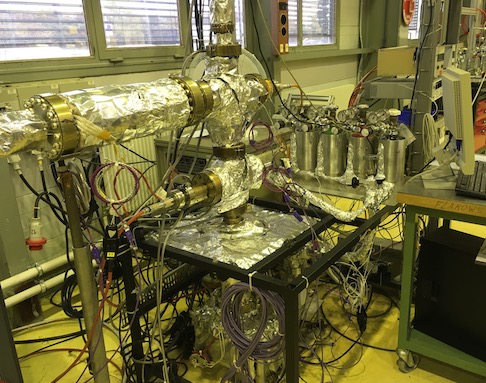

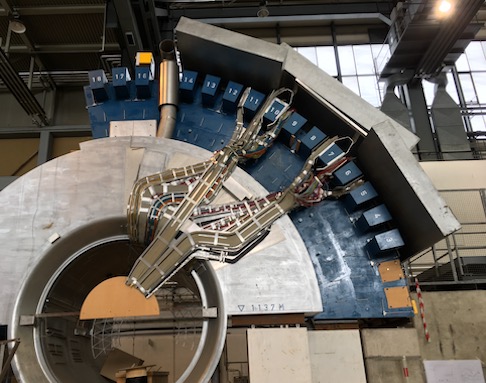

ITER ("The Way" in Latin) is one of the most ambitious energy projects in the world today. In southern France, 35 nations are collaborating to build the world's largest tokamak, a magnetic fusion device that has been designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy based on the same principle that powers our Sun and stars.

ITER will be the first fusion device to produce net energy. ITER will be the first fusion device to maintain fusion for long periods of time. And ITER will be the first fusion device to test the integrated technologies, materials, and physics regimes necessary for the commercial production of fusion-based electricity. The ITER Members—China, the European Union, India, Japan, Korea, Russia and the United States—are now engaged in a 35-year collaboration to build and operate the ITER experimental device, and together bring fusion to the point where a demonstration fusion reactor can be designed.

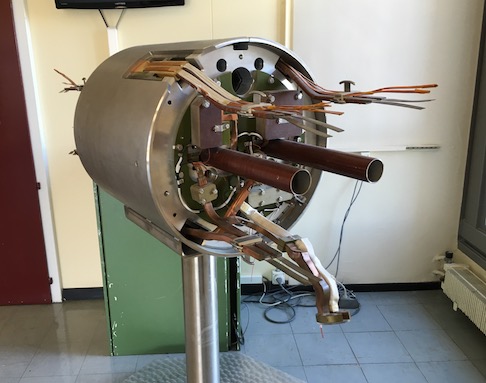

Still under construction, ITER’s most vexing problem with their UHV junctions has been excessively high bolt loading. A high percentage of ITER’s metal sealed junctions are failing due to the inability of the fasteners to fully crush the gaskets. Bolts are routinely breaking under the extreme loads. Bostec has engaged in a redesigned effort to convert most of ITER to low-force X-Energized seals.

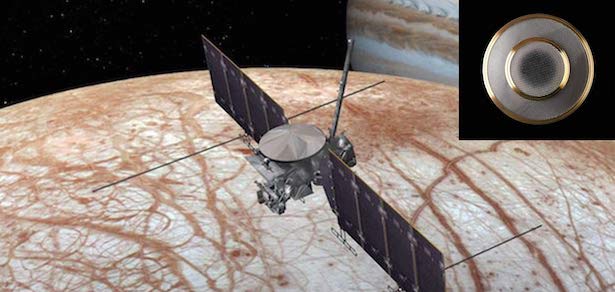

Sierra Nevada Space Corporation and Southwest Research Institute have both chosen Bostec for their portions of the Europa Clipper mission to Jupiter. BOSTEC’s proprietary low-force clamping approach keeps mass to a minimum for a spacecraft flying to one of Jupiter’s moons. The pictured custom BOSTEC seal, made of gold-coated titanium, passed stringent tests to be selected for the Jupiter mission.